Accumulation rollers - a special type of driven roller

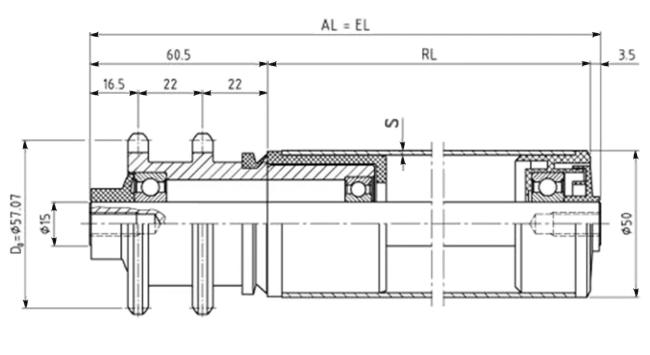

Accumulation rollers of conveyors for unit material handling are a subspecies of driven rollers. The special feature of these rollers is the connection between the roller shell and the sprocket. This connection ist not fixed like in case of driven rollers, but it is movable and torque dependent. The torque is transmitted from the sprocket to the roller shell by friction via a special plastic sliding bush. This is why such rollers are also known as friction rollers. They are used in automated conveyors for unit material handling with buffer sections.

The use of accumulation rollers makes it possible to accumulate the units of piece goods, such as parcels, crates or boxes, on the conveyor line. It is not necessary to switch off the drive when a package (unit) hits an obstacle or stopper.

If the defined torque is exceeded, the chain sprocket slips in the roller tube respectively the plastic sliding bush. As soon as the stopper is removed and the way on the conveyor is free again, the package continues its movement on the rollers.

We use sprockets with hardened tooth flanks. This results in significantly higher wear resistance and consequently a much longer service life for the conveyor rollers.

By coating the roller tubes with rubber or polyurethane, the impact loads on the rollers and the transported goods can be reduced. The rubber coating also improves the adhesion between the transported goods and the running surface of the roller, which reduces or nearly eliminates slipping of the transported unit on the roller.

A conical coating or the use of conical plastic elements is used for accumulation rollers that are installed in the curved sections of conveyors for unit material handling.

We would be pleased to offer you roller that are optimally adapted to your application. We look forward to your inquiry!

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0