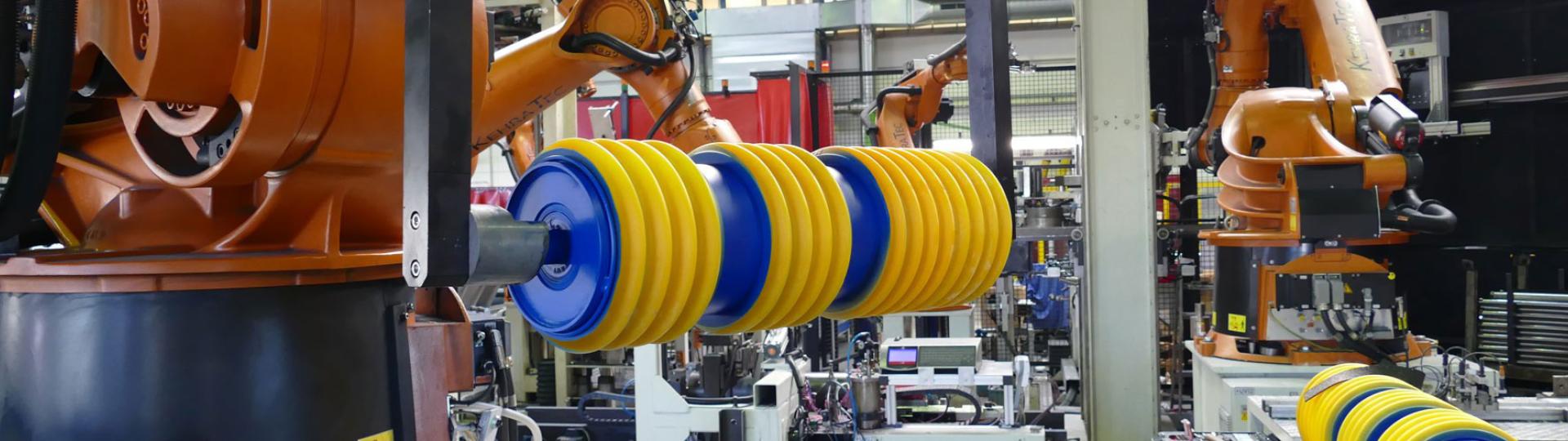

Material purchasing and cutting - first steps in the production of an conveyor roller

The material purchasing and cutting are the first steps in the production process of an conveyor roller - this is where the basis for the high quality of the end product is created.

The materials, half-finished parts and other elements required for the production of conveyor rollers and idlers are purchased in accordance with the relevant standards and subjected to strict quality controls upon delivery. For many purchased materials, e.g. for the tubes, our own factory standards apply, which further restrict the specifications of the generally applicable standards and thus ensure even greater precision and even higher quality of our products.

The purchased goods are stored in one of our automated warehouses only after they have been approved by our quality assurance department. We always keep stock levels above a certain minimum required level, which allows us to shorten delivery times and offer our customers more favorable conditions.

The half-finished parts (tubes, round bars, etc.) are cut to order on automated, high-performance machines. After cutting, the blanks for the shaft are taken to the turning department. The cutted tubes are usually transported to the welding department, where they also find their way to the turning department after the bearing housings have been pressed in and welded.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0