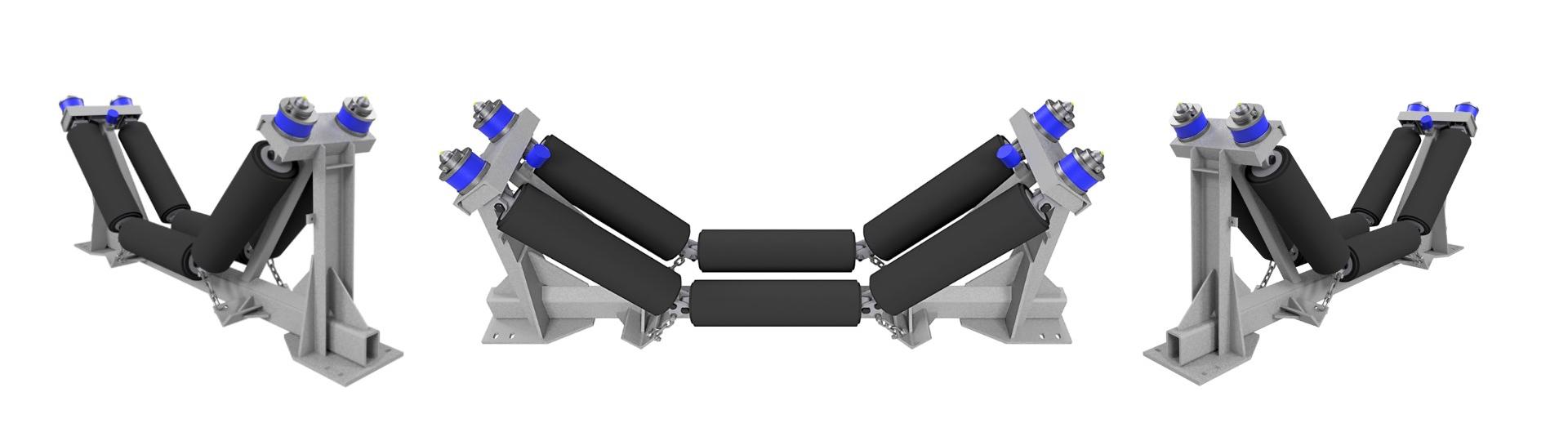

Quick garland replacement - essential for high conveyor availability

Fast installation or replacement of the garland means short installation times or only short maintenance downtimes. This significantly increases the availability and therefore the efficiency of the belt conveyor respectivelly other machines whose operation depends on the operation of the belt conveyor.

A complete change of an garland is completed in around five minutes in German lignite mines. This usually involves a team of four employees and a crane. It is not necessary to lift the belt in the process as long as there is no bulk material on the conveyor belt.

Garland change possible in limited spaces

However, sometimes it is difficult or even impossible to use larger lifting machines due to particularly inaccessible installation locations or particularly confined spaces - such as in the feed areas. We have developed our Garland Installation Device for exactly such situations.

It fits perfectly with our heavy-duty impact garlands and allows garlands to be changed without lifting the belt and without the use of other lifting equipment in around 10 minutes. When working simultaneously at both ends with teams of two employees each equipped with our Garland Installation Devices, even in only 5 minutes.

The demo video of the Garland Installation Device

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0