The pulley construction designs can vary greatly. We have listed the most important features of drum pulleys for you here.

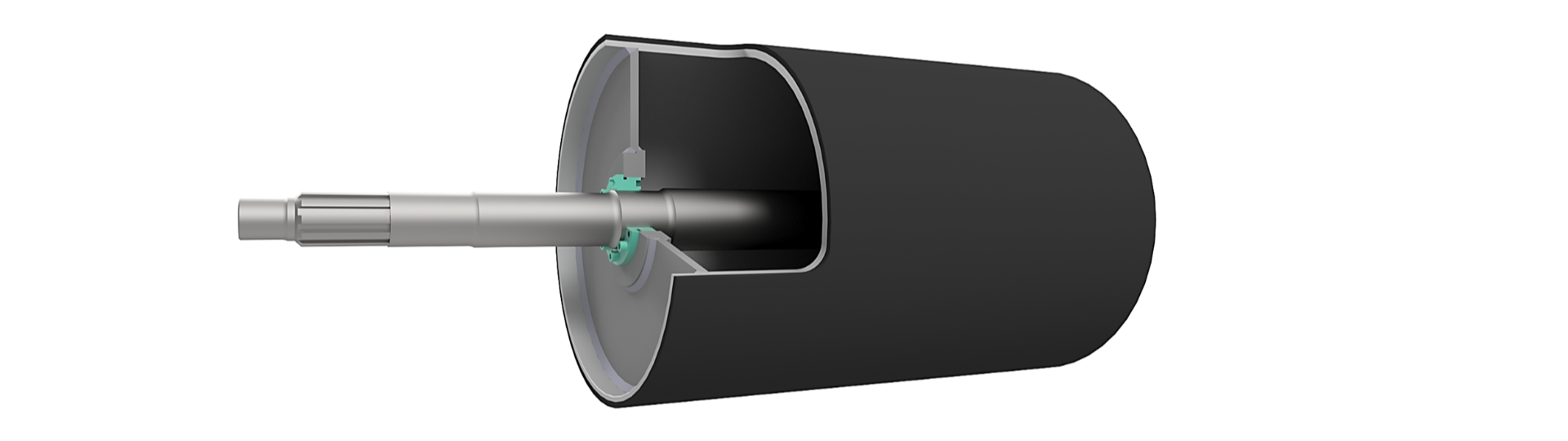

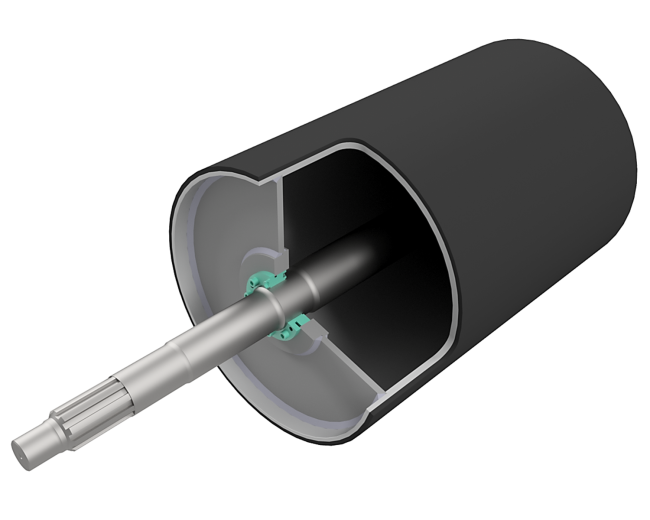

Bearing:

- with external bearings and co-rotating shaft ("live" shaft)

- with internal bearings and non-rotating shaft (pulley with internal bearings)

Shafting:

- solid shaft

- bending resistant hollow shaft

- with shaft stubs (no solid throughout shaft).

Connection of the shaft:

- material connection (welded)

- form-fit connection (e.g. with feather keys)

- force-fit connection (with clamping sets, with press fit, with shrink fit)

Material:

- structural steel

- stainless steel

Laggings and coatings:

We are happy to offer you all types of coatings that we also use in the manufacture of conveyor rollers and idlers. Depending on the application, the following coatings can be used:

- hot vulcanized rubber coating;

- casted PU coating;

- ceramic coating (different types depending on pulley application);

- combinations of the coatings listed above (e.g. ceramic and PU).

We can adapt both the properties of the elastomer coatings (rubber, PU) and their shape specifically to your application. For example, we can offer you cylindrical, crowned, tapered or specially according to your specifications turned drum pulleys. The diamond-shaped profiling or other type of profiling of the lagging are also possible.

We are happy to offer you numerous types of pulley designs - both belt conveyor drum pulleys and pulleys for other applications. If required, we can optimize them specifically for your applications. We specialize in drum diameters of up to Ø500 mm with shell lengths of up to 4,000 mm. Other sizes are available on request.

We look forward to your inquiry!

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0