Return rollers Premium - for highest loads with particularly high requirements:

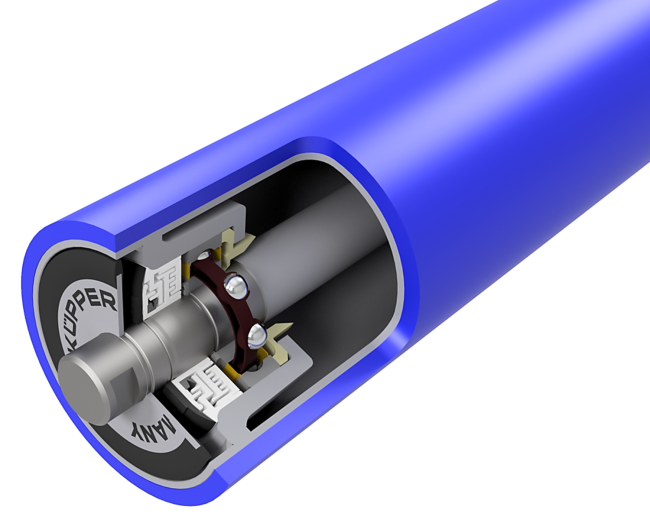

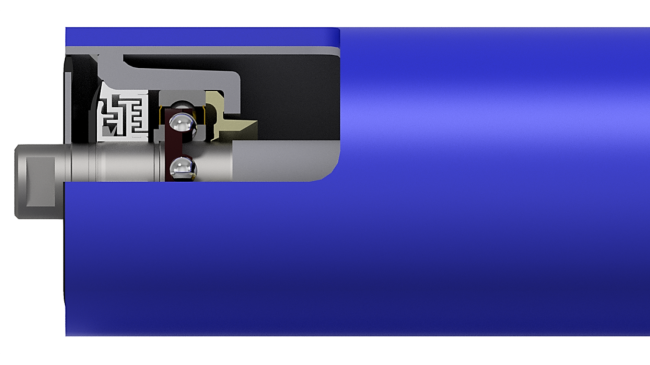

- Roller tube manufactured from longitudinally welded steel tubes acc. to EN 10305-3 with restricted tolerances (Küpper standard);

- Material of the roller tube: steel S235JR acc. to EN 10025-2

- Forged bearing housing made of steel C15 acc. to EN 10267-2 or S235JR acc. to EN 10025-2

- Fit of the bearing seat in the bearing housing: IT7 acc. to EN ISO 286-1

- Shafts made of solid material acc. to EN 10083-2 or bending resistant hollow shaft made of precision tube with welded-in shaft ends

- Fit of the bearing seat on the shaft: IT6 acc. to EN ISO 286-1

- Deep groove ball bearing AKT acc. to DIN 625-1, 2Z shields, plastic cage, lubricated for life, greasing designed for specific applications

- Bearing sizes 6306 - 6310

- ISO tolerance class 5 (P5) acc. to DIN 620-2

- Radial internal clearance for deep groove ball bearings C4H acc. to DIN 620-4

- Additional inner seal made from high-quality material

- QLR hybrid seal: patented, lubricated for life, particularly effective when exposed to splash water and dust

- Rubber roller protector extends the service life of the QLR seal additionally

- Optionally with weather shield (protection against blocking of the rollers by jammed stones)

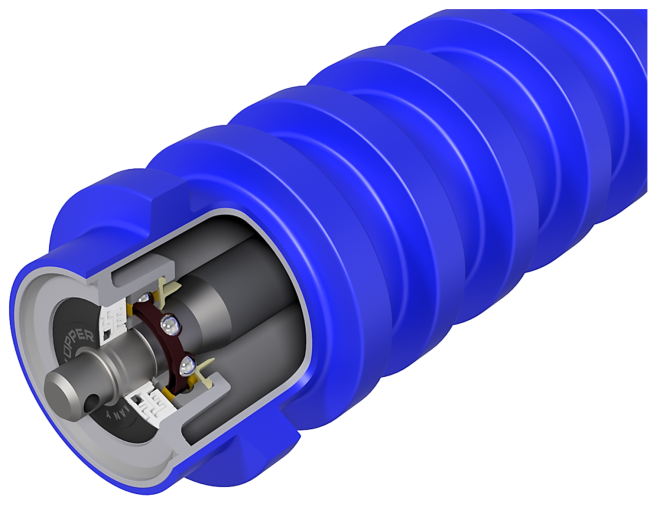

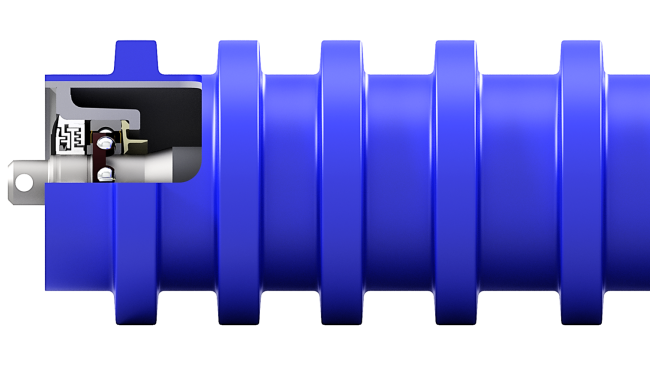

- Casted PU coating

Support ring arrangement

Return rollers with cast polyurethane support rings | |||||

Ø Ring | 180 | 194 | 194 | 219 | 250 |

Ø Tube | 108 | 133 | 194 | ||

U1 | ⏺ | ⏺ | ⏺ | ⏺ | ⏺ |

U2 | ⏺ | ⏺ | ⏺ | ⏺ | ⏺ |

U3 | ⏺ | ⏺ | ⏺ | ⏺ | ⏺ |

U4 | ⏺ | ⏺ | ⏺ | ⏺ | ⏺ |

Legend for U-series support ring arrangements see here.

Coating

Return rollers with casted polyurethane coating | |||||||||

Ø Shell | 116 | 122 | 133 | 143 | 150 | 160 | 167 | 173 | 180 |

Ø Tube | 108 | 133 | 159 | ||||||

Ø Shell | 185 | 191 | 204 | 208 | 220 | 230 | 250 | ||

Ø Tube | 177 | 194 | 219 | ||||||

Other sizes and desings on request.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0