Troughing idlers

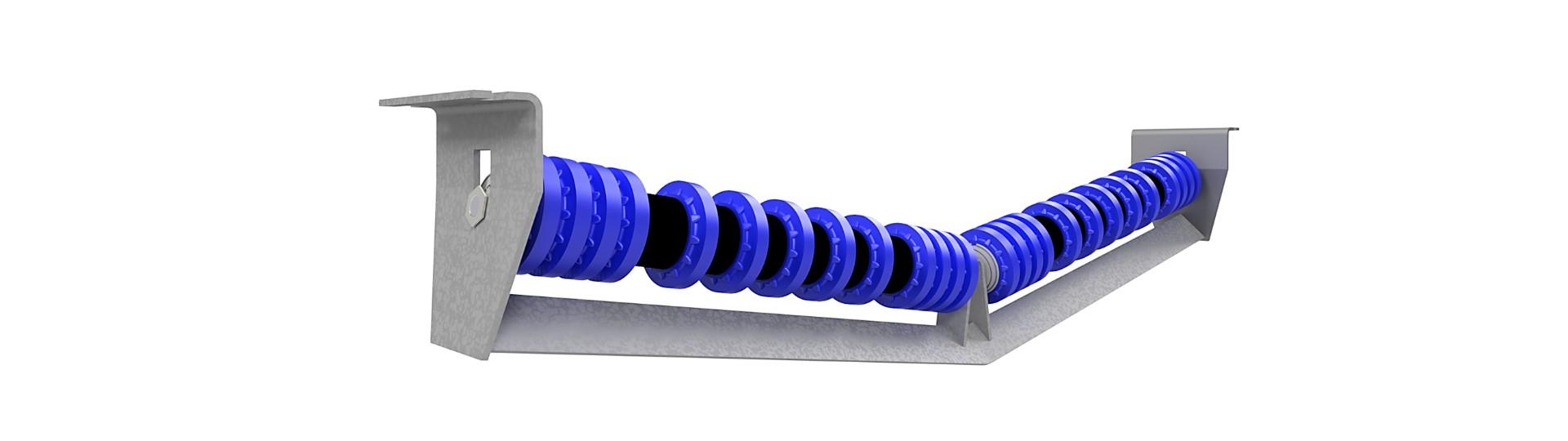

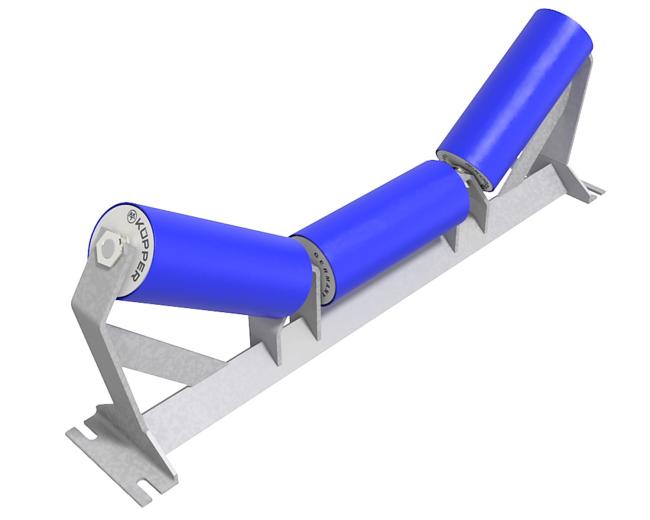

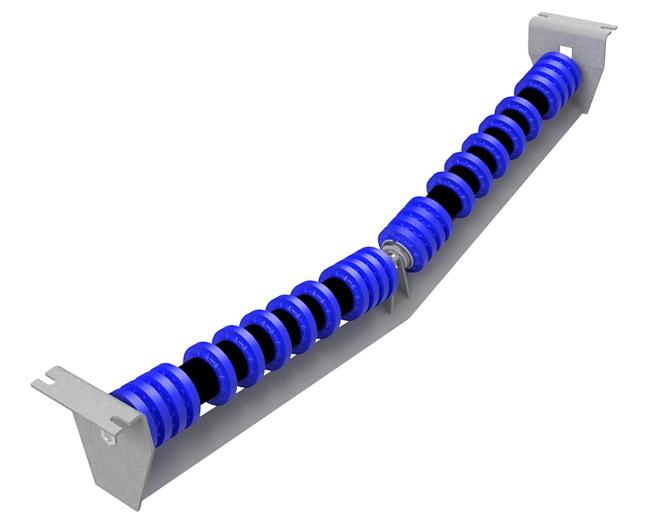

The terms "troughing idlers" and "troughing idler frames" refers to all standard rigid frame idlers that are used in the upper and lower runs of a belt conveyor with a troughed belt.

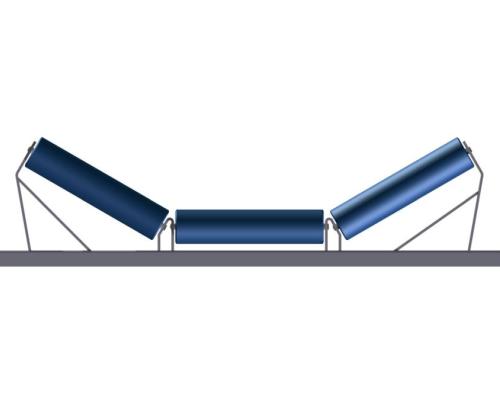

To increase the maximum possible conveying capacity of a belt conveyor, the conveyor belt is shaped in the form of a trough. Troughing the belt improves also the belt tracking and reduces the spillage. The belt is held in this shape through the idler frames. This is probably how the terms "troughing idler" and "troughing idler frame" comes about.

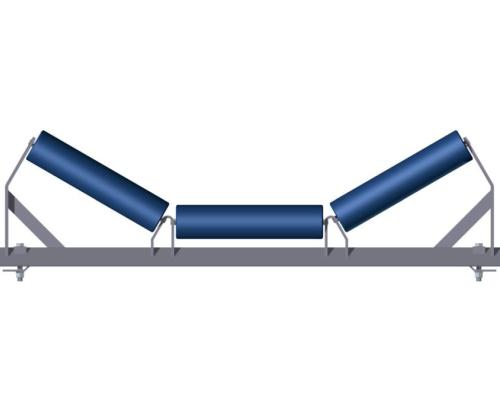

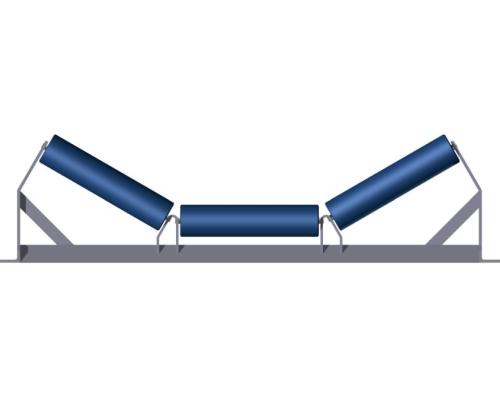

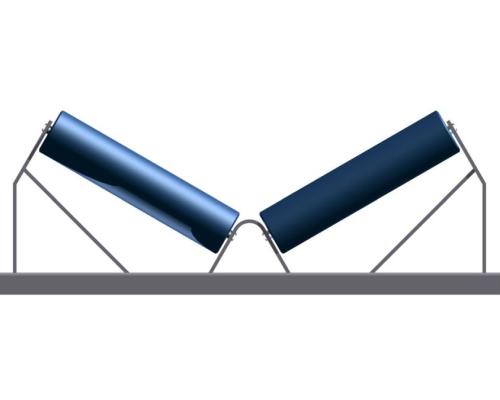

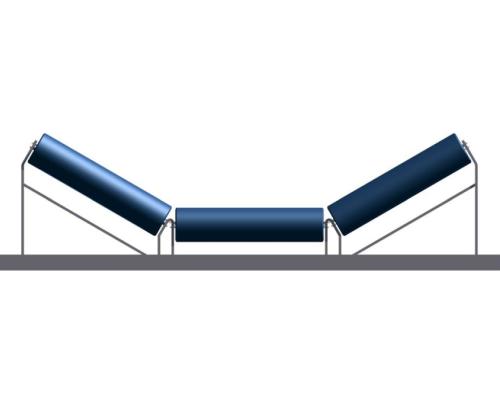

The construction of the idler frames determine the angle between the side rollers and the horizontal plane - the so-called "troughing angle".

Depending on the number of rollers in an idler, the idlers are called 1-part, 2-part, 3-part, etc.

In most cases, 3-part idlers with a troughing angle of 30° or 35° are used in the upper run of the belt conveyor. In the lower run, 2-part idlers with a troughing angle of 10° or 1-part flat idlers are usually used.

We are happy to offer you both - just the idler frames and the complete troughing idlers with corresponding conveyor rollers.

We look forward to your inquiry!

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0