The guide rollers are used for both the bulk material and unit material handling.

In belt conveyors, they are usually installed laterally at a certain distance from belt edges to protect against belt misalignment. This prevents damage caused by belt misalignment, e.g. damage to adjacent structures, destruction of belt edges, etc. The belt misalignment can then only progress to a certain extent, which is defined by the installation position and geometry of the guide rollers. It is important to understand that this measure cannot eliminate the belt misalignment and is only an emergency safety measure.

All tracking idlers in our range are also equipped with vertically installed guide rollers on both sides.

In sidewall belt conveyors (conveyors for horizontal, inclined and vertical conveying; also called "Z-conveyors" or "vertical belt conveyors") these rollers are also used as idler rollers or support rollers and hold the conveyor belt in position.

In piece goods conveyor systems, the guide rollers can be used for lateral guidance or steering of the piece goods. Due to their relatively short length, the term "stub rollers" is also commonly used.

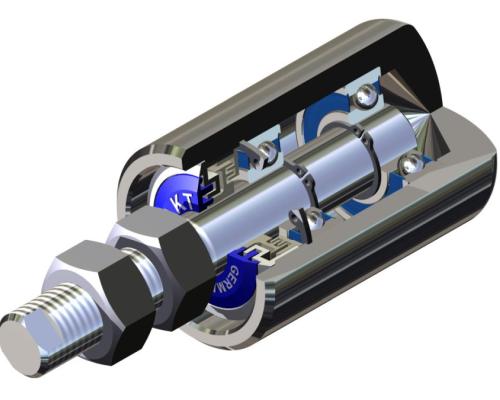

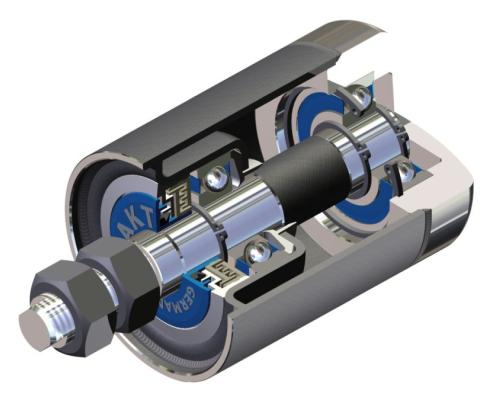

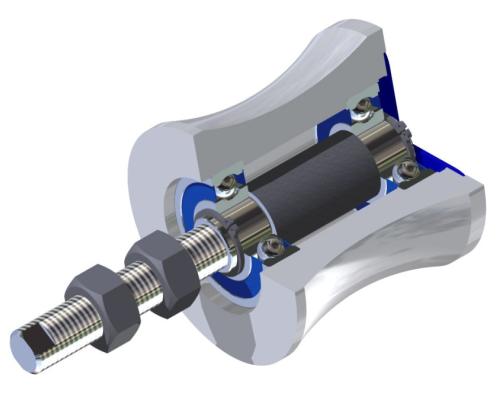

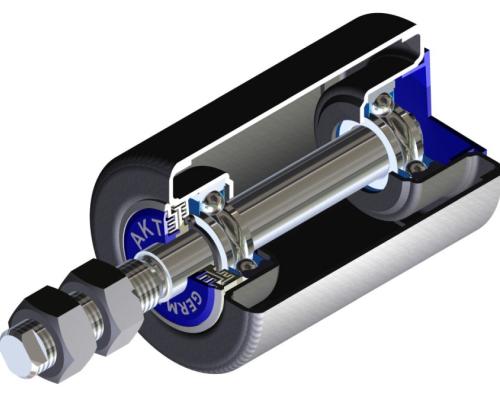

Using our know-how, best suited technologies and parts, which we take to produce our conveyor rollers, we are able to create long lasting high-quality guide rollers. In many cases it is also very helpful to use our patented QLR hybrid seals, to achieve the highest level protection of guide roller bearings against dust and water.

Of course, customized solutions are also possible. We look forward to hearing from you!

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0