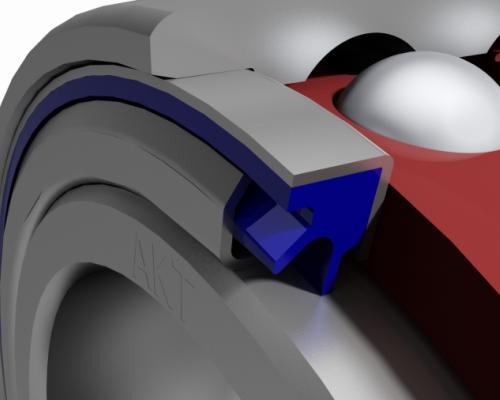

The AKT idlers and track rollers for the field of airport technology stand out due to a high degree of wear resistance, smooth running and resistance to the ingress of dirt or moisture. In this area in particular, it is especially important to make rolling bearings and idlers durable and yet easy to replace.

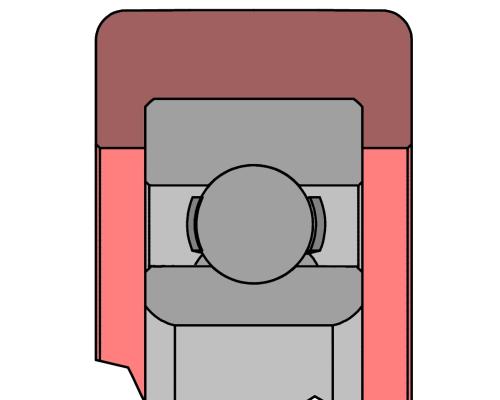

In the development of rolling bearings and track rollers, uour wide-ranging expertise in sheathing with plastics allows us to combine the advantages of several materials and thus manufacture theoptimally suitable AKT product for the most diverse applications.

Our specially optimized for this application LBR idlers, but also other idler types, installed in various means of transport of airport logistics, make an important contribution to the fast and smooth handling of heavy ULD containers and pallets for air freight.

The development teams of both sites work daily to further improve the existing products and thus increase your productivity, profitability and safety.