In 1933 Artur Küpper founded his company in Velbert Tönisheide. The Name AKT has been developed over the years into a quality brand for track rollers and roller bearings. Now AKT is run in its third generation with Mrs Susan Küpper at the helm.

Well beyond the borders of Germany, AKT is considered internationally as a centre for competence for customer-specific bearing solutions. Our products can be found in many applications, in which something should be moved, rotated or conveyed - even under extreme conditions.

Wherever around the world the topic of bearings comes up, the AKT brand makes an appearance. We offer our customers the most economical and innovative products and solutions in the field of track rollers and bearing technology. Close cooperation with our customers and individual support are at the heart of every milestone. Important for us is the cooperation with our customers. Our Customer gets individual support in every project section.

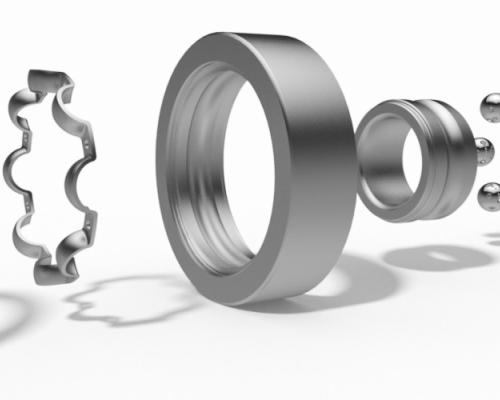

Our in-house product portfolio includes tailor-made roller bearing types and units with unique features. This will offer our customers a lasting competitive advantage. Your best solution is our task for your bearing application. We are happy to receive your inquiries.

In this video you can see an insight into our production

Bearings for extreme temperatures

In many customer applications with high temperatures (over 200°C), standard bearings will not fulfil the given requirements. These extreme conditions require an adapted bearing design with a special heat treatment and well-chosen construction materials. Especially the choice of matching high-temperature lubrication and the correct calculation of the re-lubrication intervals do indeed play a fundamental part for a long bearing lifetime under these conditions.

Bearings / track rollers with Corrprevent

The functional capability of the bearings and track rollers is mostly influenced by the conditions of their running surfaces. Beginning corrosion and increasing wear are the main reasons for an early bearing failure. They are mostly caused by the coaction of aggressive detergents and moisture in areas with temperature fluctuations. The Küpper Corrprevent coatings protect our products from external influences and increase their life time.

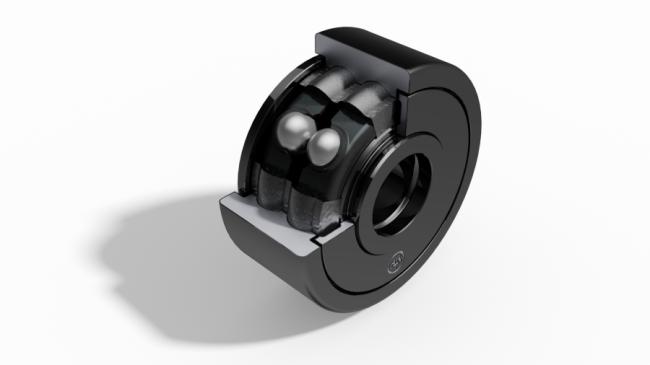

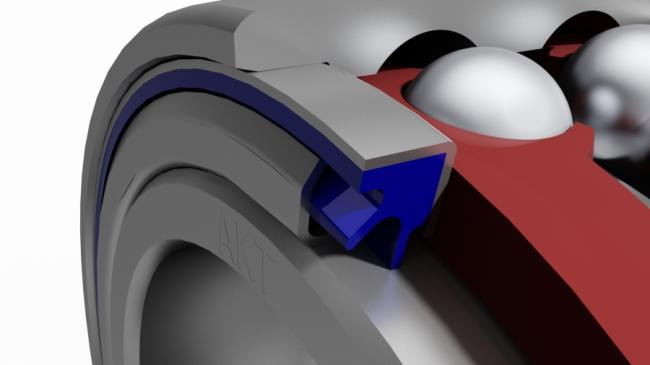

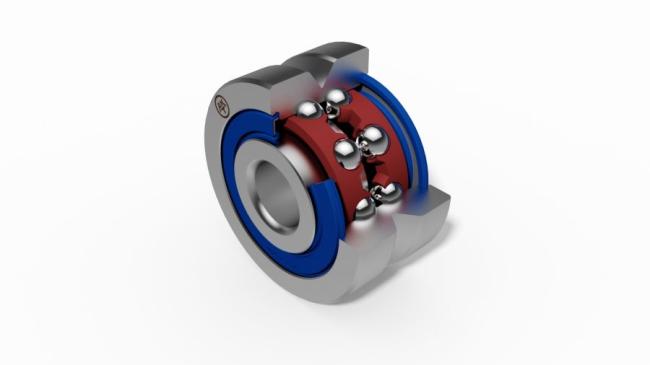

Sealing systems for bearings / track rollers

Insufficient sealings have a large share in the main reasons for bearing failures. The requirements on a sealing system for bearings can be very versatile and must therefore be accurately examined for each type of product and environmental conditions. The sealing systems developed by Küpper offer a permanent protection for your bearings and track rollers even under extreme conditions.

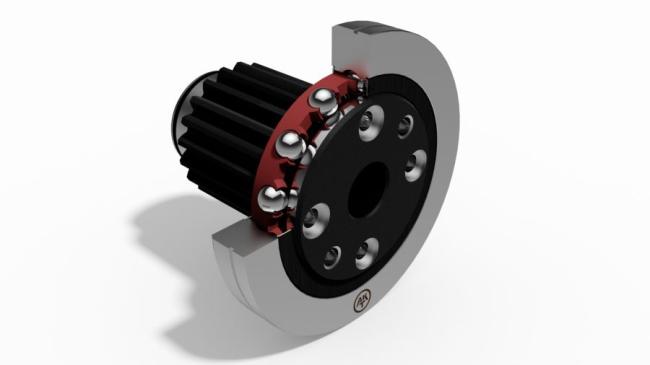

Tailored solutions for bearing applications

Standard bearings often do not meet market requirements for ongoing performance enhancements, which is why we create customized solutions for specific demands. By merging various machine elements into an assembly group, we create systems tailored to our customers’ demands with higher performance, fewer downtimes, and reduced maintenance efforts with only minimal space requirements.

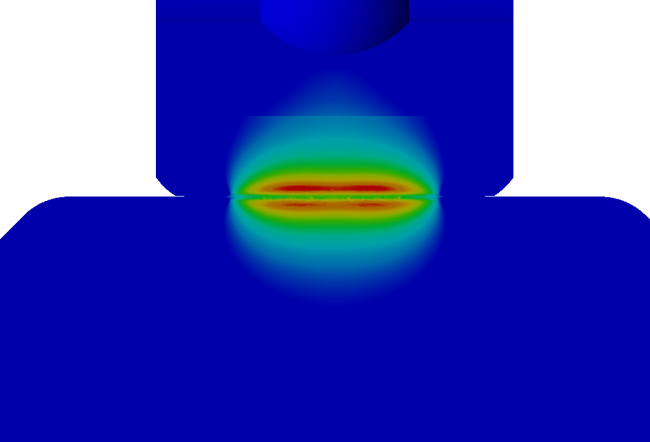

Optimised profile shapes for track rollers

For many installation situations, the critical factor is not the load rating of the bearing arrangement within a track or yoke type track roller, but the insufficient wear resistance in the contact area between the outer ring and the rolling partner (rail). The outer rings, which are usually thick-walled, can lead to premature wear on the rolling partner and thus to failure of the entire units if the profile shape is selected incorrectly.

TIME-TO-MARKET

Working together, we develop with you in a timely manner, series production to maturity including installation and on-site service.

As specialists, we accompany all process steps taking into account the feasible time frame, including the final commissioning on site. This means the complet development, design, production, assembly and extensive quality testing with our in-house bench testing equipment.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache