ATEX conveyor rollers, garlands and idlers - explosion-proof and antistatic

We are happy to offer you ATEX conveyor rollers, idlers and roller garlands specially designed for use in potentially explosive atmospheres. We enclose a corresponding declaration of conformity according to EC Directive 2014/34/EU with the correspondingly marked products.

Almost all types of our conveyor rollers can be designed as ATEX rollers: both conveyor rollers for bulk material handling and for unit material handling.

The testing of the leakage resistances to ensure the electrical conductivity of the conveyor rollers and idlers is carried out for all components used by our quality assurance. This concerns not only classic conveyor rollers with steel tubes, but also conveyor rollers with coating, lagging or rings made of elastic materials such as rubber or polyurethane.

In addition, our conveyor rollers, roller garlands and idlers have the necessary approvals for operation underground, e.g. in deep coal mines.

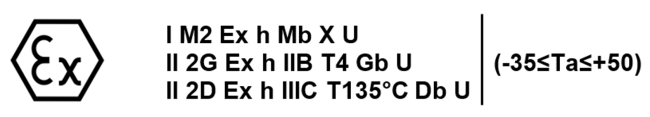

Our products meet the requirements of the following protection class when properly installed in the overall system:

Legend:

I M2: | Equipment group I: equipment for use in mining; equipment category M2 |

h: | ignition protection type "constructive safety" according to DIN EN ISO 80079-37 |

Mb / Gb / Db | Equipment Protection Level (EPL) |

X: | In the event of the occurrence of the hazardous explosive atmosphere, the equipment shall shut itself down |

U: | Designation of component |

II 2: | Equipment Group II: Equipment for applications other than mining; equipment category 2 |

G: | Explosive atmospheres caused by involved gases, vapors, or mists atmosphere |

D: | Explosive atmosphere caused by involved dusts |

IIB: | for gases, vapors, and mists of gas group IIB |

IIIC: | for Group IIIC dusts |

T4: | suitable for media with a self-ignition temperature > 135°C according to temperature class T4 |

135°C: | The maximum surface temperature in operation considering safety factors according to DIN EN ISO 80079-36 is 135°C |

-35°C ≤ Ta ≤ +50°C: | The allowable ambient temperature for operation is a minimum of -35°C and a maximum of +50°C |

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0