Pulley designations and terms

Most of the pulley designations and terms for the pulleys used in belt conveyors for bulk material handling are defined in VDI 3622. The DIN 22101 primarily provides the basis for the calculation and design of belt conveyor pulleys.

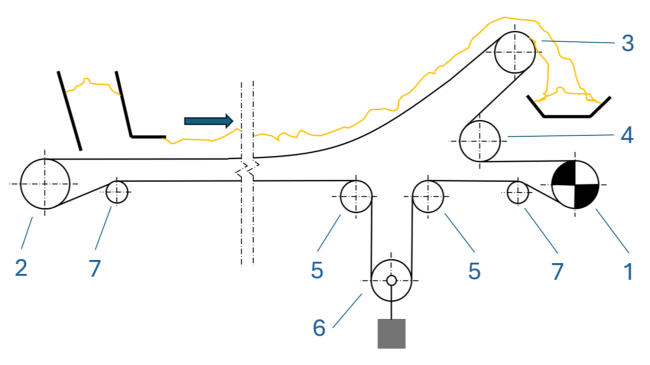

Pulley designations on the scheme:

1 - Drive pulley

2 - Tail pulley / Return pulley

3 - Head pulley / Discharge pulley

3, 4, 5 - Bending pulleys

6 - Tensioning pulley / Take-up pulley

7 - Deflection pulley / Snub pulley

The belt conveyor pulleys are divided into three main groups according to their function:

- Drive pulleys

- Bending pulleys (wrap angle > 30°)

- Deflection pulleys (wrap angle ≤ 30°)

The pulleys are also given different names depending on their installation position within of a belt conveyor.

| Installation position within of a belt conveyor | Possible designations | Comment / description of the function |

| Head of the belt conveyor | Head pulley, discharge pulley, drive pulley | The term "head pulley" is the generic term for all large diameter pulleys in the head of a belt conveyor. The goods leave the conveyor belt at the discharge pulley. By definition, a drive pulley is always driven. In many belt conveyors, the head pulley is at same time both the discharge pulley and the drive pulley. In larger and more complex belt conveyors, this does not necessarily have to be the case - here, several drive pulleys can even be installed in the head of a belt conveyor, whereby the discharge pulley does not necessarily have its own drive (see the scheme above). |

| Tail of the belt conveyor | Tail pulley, return pulley, tensioning pulley | The tail pulley is installed in the rear part of a belt conveyor. It is also called the return pulley , as it redirects the belt from the lower run into the upper run. If this pulley is used to set the required belt tension, it can also be referred to as a tensioning pulley. |

| Tensioning station | Tensioning pulley, take-up pulley | If the conveyor belt system has an explicit tensioning station (does not always have to be in the rear part of the conveyor), the heart of this station is the tensioning pulley. If a counterweight is used to set the required belt tension, the counterweight is attached to a take-up pulley. |

| Various positions near large diameter pulleys | Snub pulley, deflection pulley, tensioning pulley | They are used to change the running direction of the conveyor belt with smaller wrap angles or to increase the wrap angle on the larger pulleys (e.g. drive pulley). |

Pulley, roller or idler?

The pulleys with internall placed bearings with smaller diameters (e.g. for smaller belt conveyors) are sometimes also referred to as "rollers". As a result, you may also come across terms such as snub roller, tensioning roller, deflection roller, pressure roller, etc.

The pulleys with externall placed bearings with smaller diameters are also sometimes referred to as "idlers". This is why you may come across terms such as live shaft idler, tension idler, deflection idler, etc.

However, these designations do not correspond to the terms used in the standards for belt pulleys. According to the standards, these parts should be referred to as "pulleys".

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0