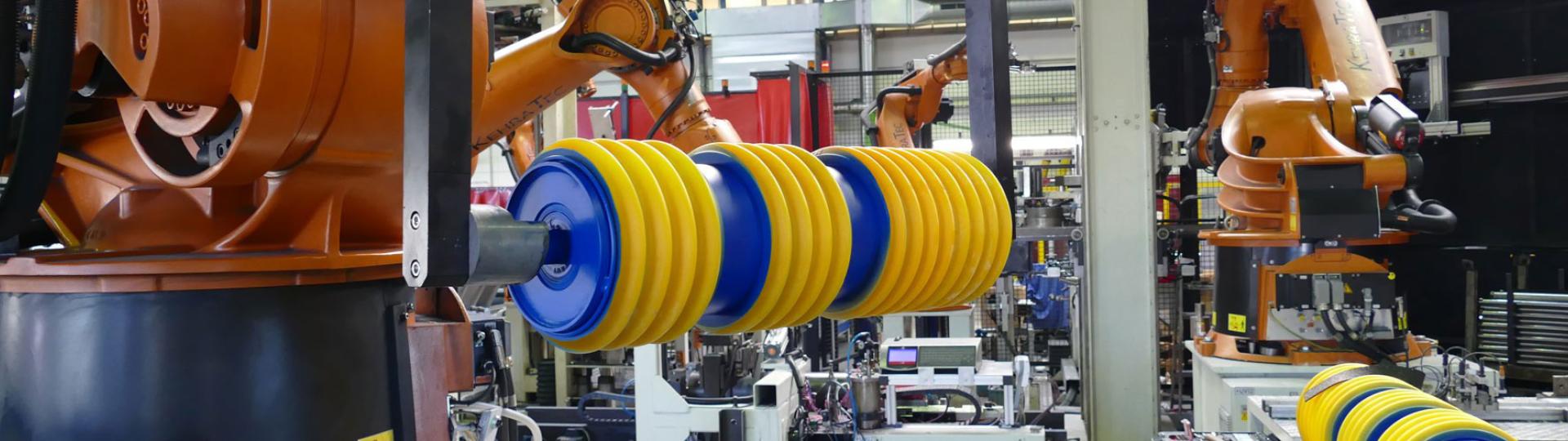

Coatings and laggings

Coatings and laggings are often useful to adapt the conveyor rollers on the operating conditions of the current application. This significantly increases the service life of conveyor rollers and idlers and boosts thus the productivity of your conveyors.

In addition to the usual laggings such as rubber or polyurethane rings, we also offer conveyor rollers and pulleys with hot vulcanized rubber coating, with casted polyurethane coating or with ceramic coating.

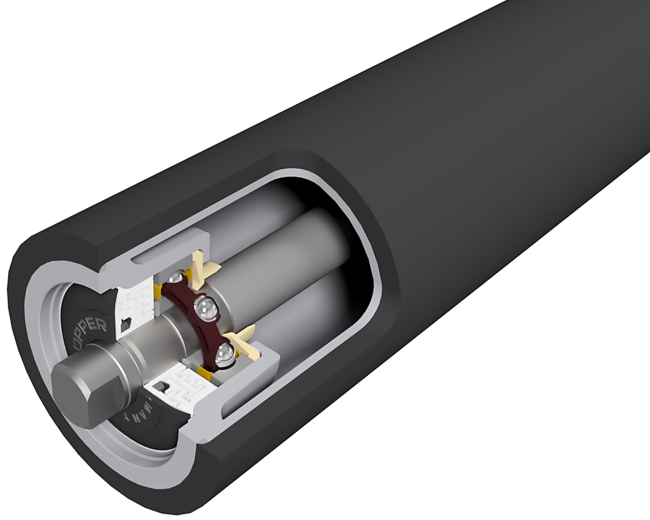

Hot vulcanized rubber coating

This type of coating is particularly often used for the carrying rollers of the impact areas (for impact rollers) in belt conveyors for bulk material handling. It is well suited as a much more durable and robust alternative to the impact rings used as standard.

However, the hot-vulcanized rubber coating has a number of important properties, which is why it is also popular in unit material handling: it is elastic, shock-absorbing and offers good traction and grip.

Ceramic coating

This type of coating is used for highly loaded rollers (e.g. deflection rollers) and pulleys when particularly high wear protection is required. Not only is it over 60 times more wear-resistant than structural steel S235, it is also chemically inert and therefore provides excellent corrosion protection.

You can find more details here.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0