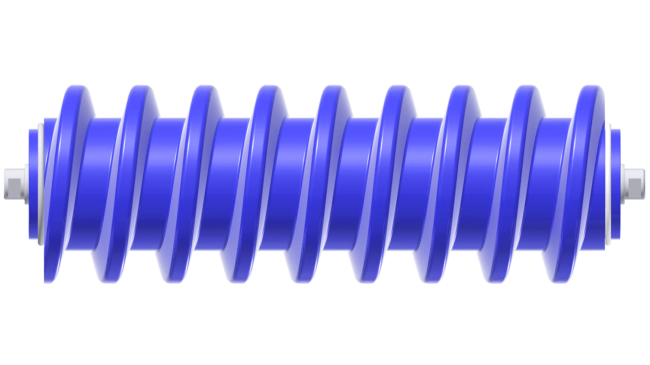

Spiral rollers

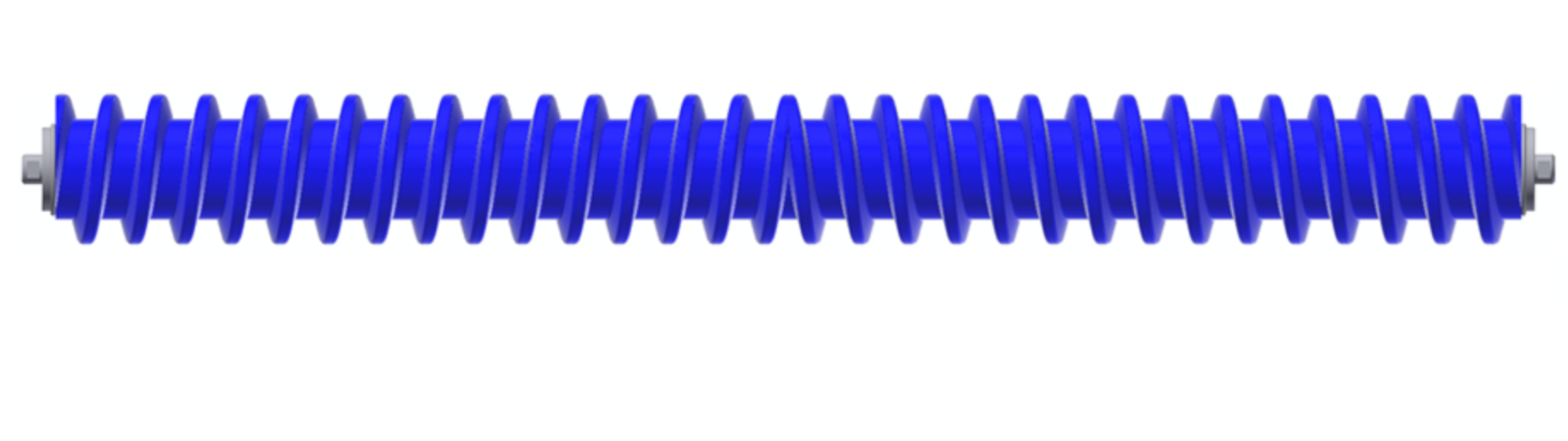

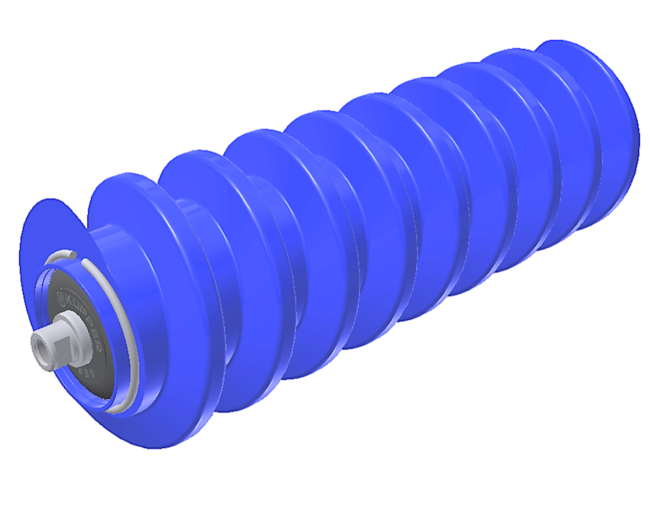

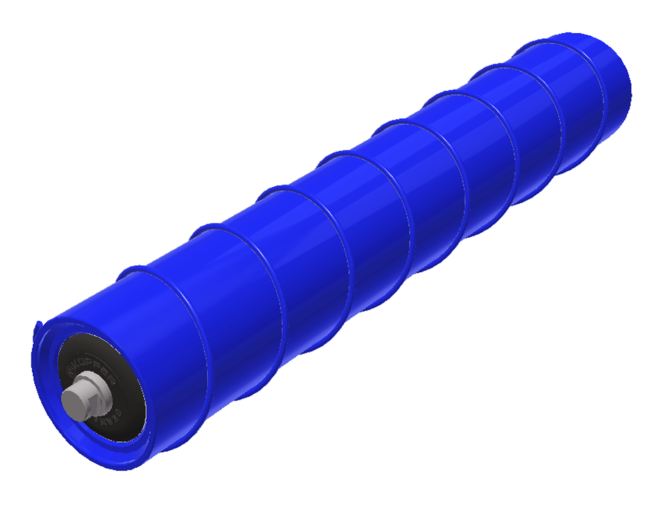

Spiral rollers, also known as "spiral rolls", are conveyor rollers with a modified shape of the roller shell. The running surface of the roller is shaped like a spiral (helix) thanks to special structures, laggings or coatings on the idler roller shell.

Such conveyor rollers are used as one of the possible solutions agains carryback. In this use case the cleaning of the conveyor belt from the bulk material particles adhering to the belt is to be improved or the falling particles of the conveyed material detached from the belt are to be conveyed to the side (see the explanations below). Spiral rollers are used both in the lower run of belt conveyors and in agricultural machinery.

The spirals can have different shapes, dimensions and directions (left or right rotation) and can be made of different materials. Our portfolio includes conveyor rollers with spirals made of steel and wear-resistant polyurethane (PU).

We particularly recommend the rollers with PU spirals for use in the lower run of belt conveyors for bulk material handling.

Cleaning properties

When contact is made with the running surface of the idler roller, the bulk material particles adhering to the belt are loosened. The cleaning properties of the spiral rollers result from the shape of the spiral and the fact that the spiral touches 100% of the contact surface of the belt when it rotates. In contrast to classic return rollers with support rings, the spiral rollers therefore do not leave any areas of the belt without cleaning.

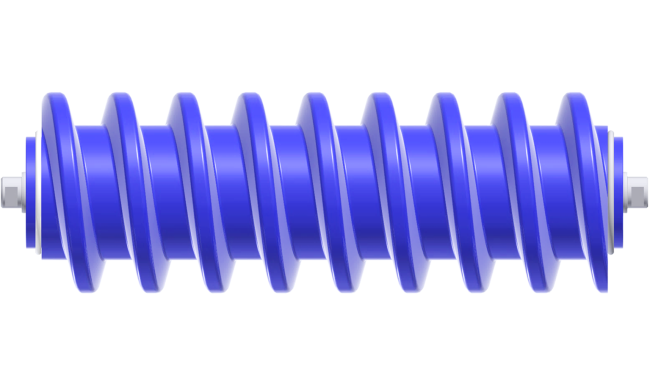

Conveying the bulk material to the side

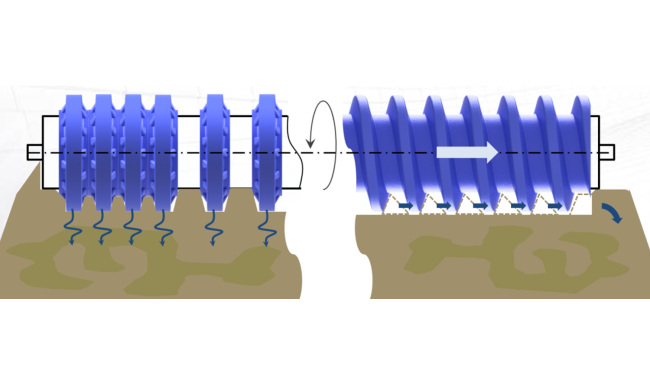

Sometimes situations occur when the bulk material accumulates in particularly large quantities under the return rollers - so large that the accumulated bulk material already touches the rollers or the rollers threaten to dig in. This is a critical condition for the conveyor rollers, which can lead to premature wear and failure of the return rollers. The spiral conveyor rollers make a significant contribution to preventing such conditions.

The spiral works like a small screw conveyor and pushes the particles in a certain direction as the idler roller rotates. This successfully helps to avoid the problem of buried return rollers. The conveying direction of the spiral roller is defined by the shape of the spiral and the running direction of the conveyor belt.

Especially when installed in combination with a trough (similar to a screw conveyor), the spiral rollers make it easier to clean the conveyor of accumulated bulk material by conveying the trickling bulk material particles to a defined side and avoiding of their sedimentation under the belt.

For larger belt widths, two rollers are often used for each return idler assembly. In this case it is advisable to use spiral rollers with different conveying directions - so that both rollers convey from the center of the belt to the outside.

Wobble rings

Wobble rings are often referred to as "spiral rings". This term is incorrect, as this type of support ring does not have a spiral-shaped running surface (helix). Similar to the real spiral (real helix), these types of support rings help to clean the conveyor belt, but do not have the function of conveying the bulk material caused by carryback in a specific direction.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0