Documentation and traceability - extremely important for quality assurance

The clearly product identification, documentation and traceability are extremely important for the quality assurance and are the necessary precondition for reliable production.

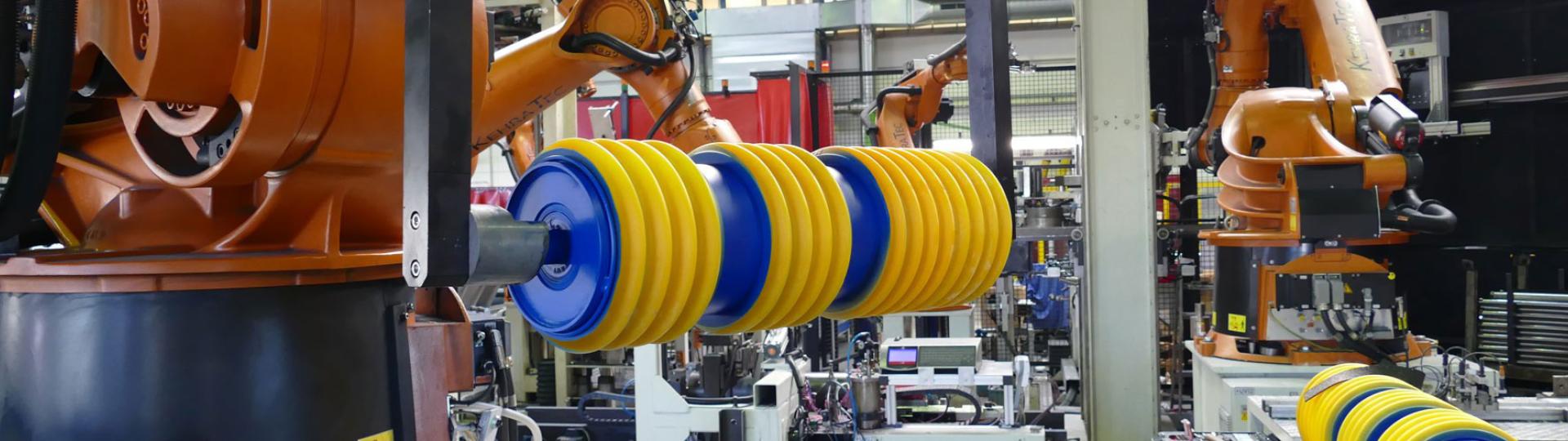

The axial play, concentricity and running resistance of each idler roller are checked in our fully automated assembling line. All measurement results are recorded for each specific conveyor roller.

If all the quality characteristics determined are within the specified tolerance limits, each roller is automatically given an ID number and the date of manufacture. This individual marking is usually applied to the face surface of the roller shaft. It is applied mechanically so that it remains clearly legible even many years after the conveyor roller has been put into operation.

This working step is a particularly important component of our quality assurance. In this way, we achieve a 100% traceability.

The values determined during roller assembling are archived and can be sent to you with every delivery on request.

The idler frames or the complete idlers can also be labeled on request.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0