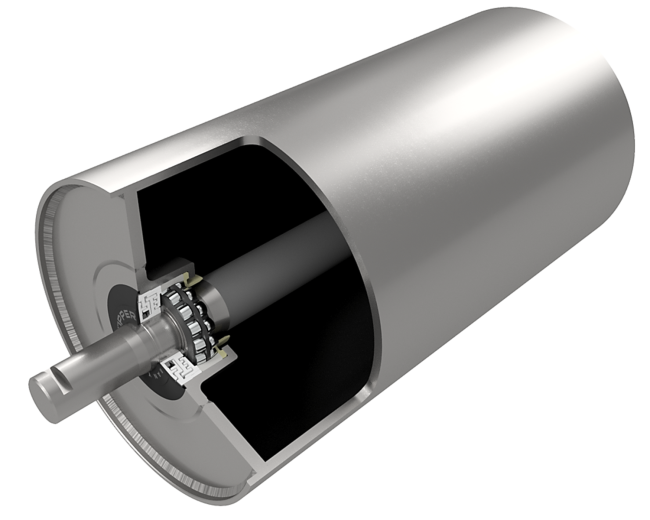

A pulley with internal bearings is a pulley with a non-rotating ("dead") shaft and bearings located inside of the pulley. This type of pulley design offers many advantages compared to a pulley with external bearings and is recommended by us in many cases.

Advantages of the internal bearing pulley design

- Lower weight - this means less material, lower transportation costs, lower load on the supporting structures and a bit simpler assembling process;

- Lower weight of rotating parts and consequently better energy efficiency, reduction of wear, lower belt tension forces during acceleration (start/stop) and lower load on the bearings of the pulley;

- More compact design due to reduced shaft length and therefore less space required;

- Efficient seals ensure longer bearing service life;

- A more cost-effective design compared to a similar pulley with external bearings can generally be achieved. This is made possible by the fact that no bearing units and clamping sets are required and more cost-effective - although no less efficient - seals from our own production are used.

What is the difference to a conveyor idler roller?

The main difference between a pulley with internal bearings and an idler roller is the application: The idler rollers do not have the function of changing the belt guidance and should consequently never have wrap angles greater than 1°- 2°. The wrap angle of the pulleys - including the pulleys with internal bearings - is considerably greater. This means that the load on the pulley always depends heavily on the local belt tension.

Your contact person

-

Idlers sales

-

+49 (2041) 177 - 227

-

Idlers and conveyor belt rollers

-

+49 (2041) 177 - 0