Rolling bearings and track rollers for the metal industry

Specially in the field of maintenance and spare parts procurement, there is often the problem of long delivery times and different dimensions for the various competitor products. This is where Artur Küpper GmbH & Co.KG starts, because by own manufacturing and design/development we are able to, respond to the demands of users, possibly existing potential for improvement to recognize and use.

Our solutions are already installed for a long time at well-known plant manufacturers and users and show that the individual adjustments have achieved significant improvements in service life and simplification of maintenance. The delivery times and the possibility to realize the dimensions individually to the installation space according to customer specifications are a big plus of our products. A modern machinery, the production accompanying documentation and the corresponding Quality testing and assurance ensure a transparent and traceable insight into our claim to a successful product.

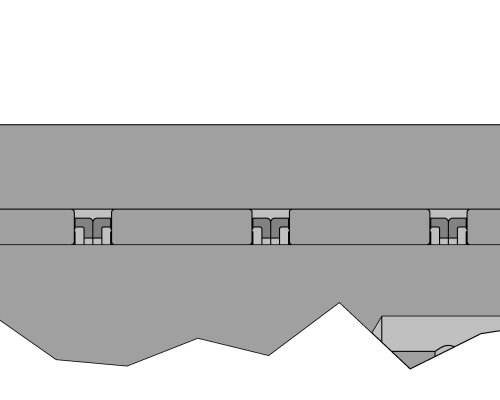

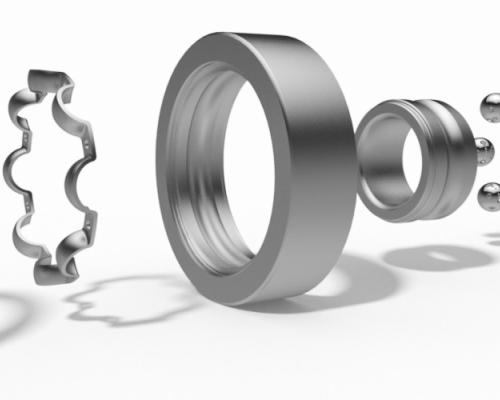

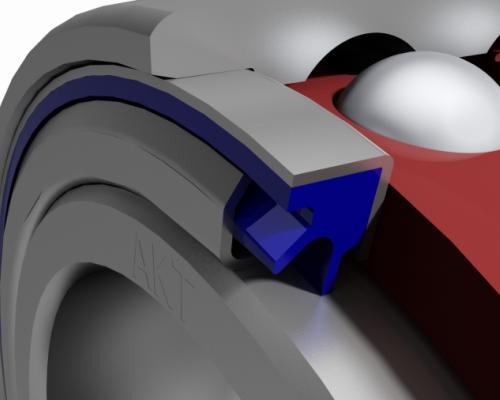

The idlers, rolling bearings and track rollers for the metalworking industry must often withstand extreme loads, impact loads and particularly high temperatures. In addition, there are the other adverse external influences, such as corrosive and abrasive dusts, which in combination with water can easily form caking on the running surfaces and extremely promote wear.

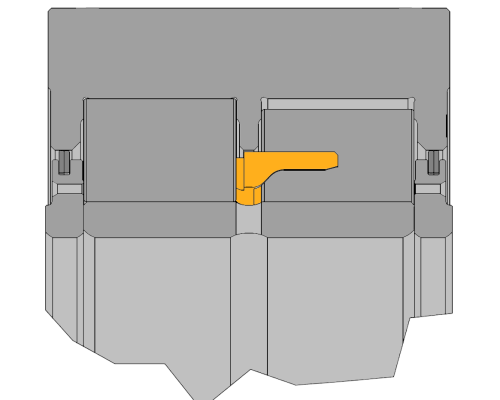

Whether particularly wear-resistant idlers for shot blast machines, heat-resistant flanged rollers for apron conveyors or back-up rollers for bending straightening systems - we will be happy to develop the optimum solution together with you, which is best suited to the given requirements and increases the reliability and availability of your equipment.

Of course, thanks to our flexible manufacturing and assembly, we can also design and manufacture entire assemblies.