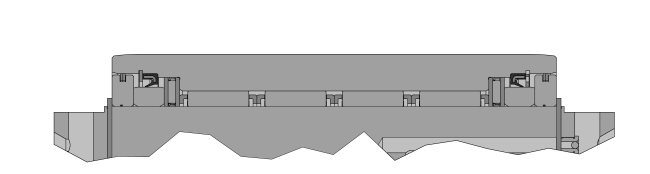

Features RLBS yoke type track rollers

RLBS yoke type track rollers double row or multi-row rolling bearings consisting of a thick-walled, usually profiled outer ring and cylindrical rolling elements (needles). Due to the design of the inner structure, low overall heights can be achieved with high load carrying capacity. Due to their special design, the choice of materials and the very accurate overall height, RLBS yoke type track rollers are used in stretch bending straightening plants or strip processing lines. The relubrication can be optionally via holes in the inner ring.

Loads

The RLBE back-up rollers are designed for the extremely high loads in rolling operations.

Accuracies

The RLBS back-up rollers are manufactured with narrowed dimensional and running tolerances. Optionally, by grouping in heights of 0.005 mm smallest height differences between the yoke type track rollers of a row can be achieved.

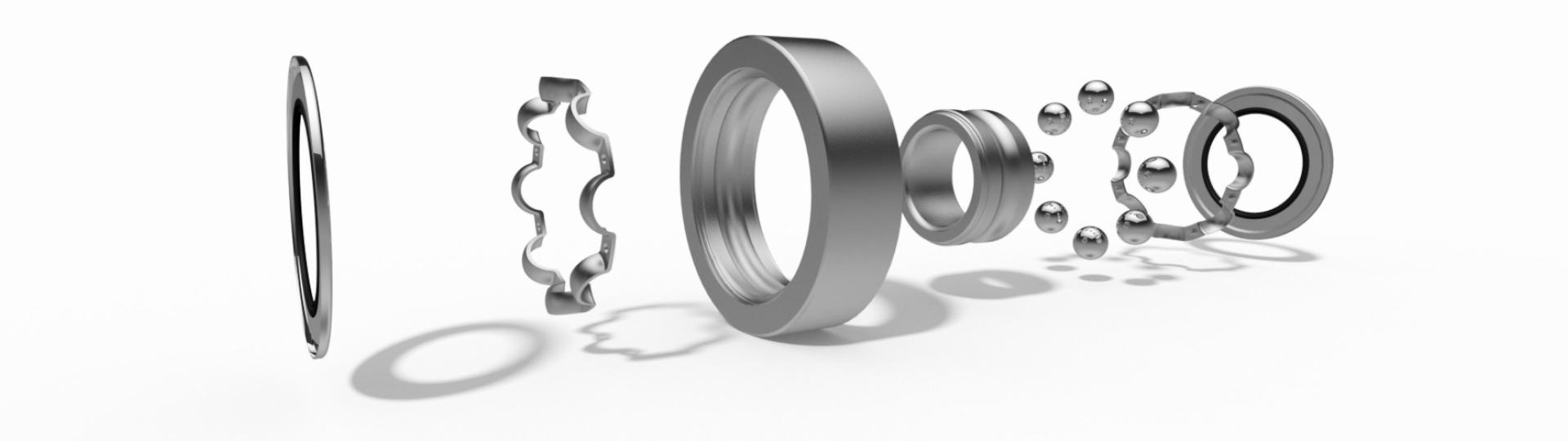

Sealing

Typically, the RLBS yoke type track rollers are designed for lifetime lubrication. The used Sealing systems usually consist of a pre-sealing to seal against coarse particles and a main sealing. Here, a combination of labyrinth sealing and grinding sealing is usually used.

Cages

WGTR back-up rollers are usually equipped with steel cages .

Materials

The outer rings of RLBS back-up rollers are made of special case hardening steels, shell hardeners, or rolling bearing steel to meet the requirements of the rolling process.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache