Intralogistics and warehouse technology

Intralogistics is all about internal information and material flows. The speed and efficiency of the material flow depend directly on the materials handling solutions used. These solutions can be very diverse and different, depending on the tasks at hand: sometimes it is a matter of transporting heavy loads - such as in goods receiving, order picking or shipping; sometimes it is a matter of significantly smaller loads, however, in combination with extremely high conveying speeds and high demands on precision - such as, e.g. in sorting or warehouse technology.

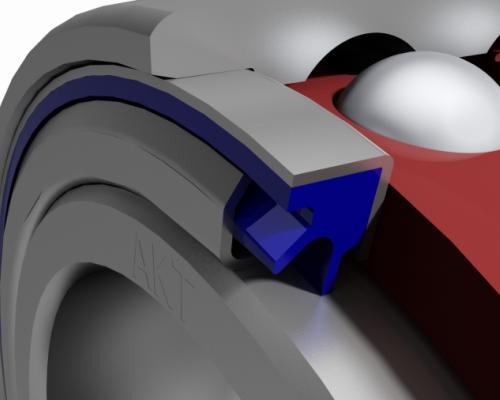

Of course, the issue of reliable seals also plays a major role here; after all, AKT products are also used in the medical and food industries.

The continuous further development of our idlers, track rollers and roller bearings ensures long-term stable motion sequences and a "smooth" process flow. The wide range of products we offer and the possibility to carry out customer-specific developments, ensure that we can always offer you a solution optimally suited to your equipment.

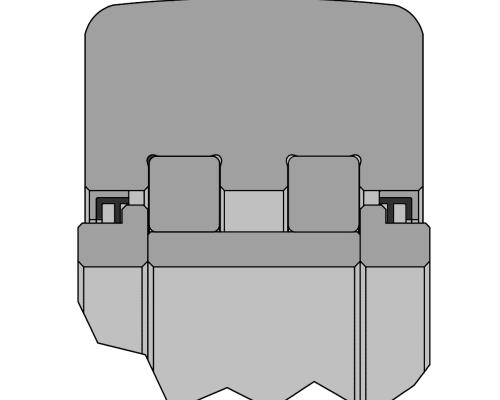

Yoke type track rollers are single or double row roller bearings consisting of a thick-walled, usually crowned outer ring and cylindrical rolling elements (needles or cylindrical rollers). The outer

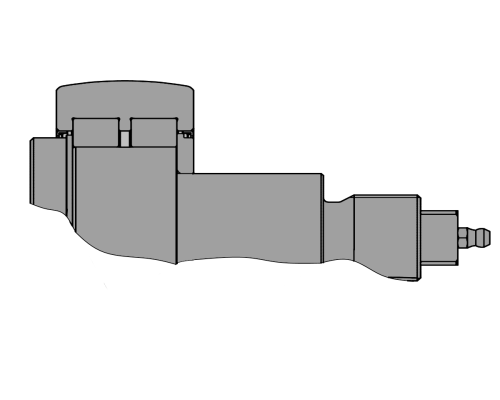

Stud type track rollers have the same internal design as yoke type track rollers, but have a combined inner ring bolt with a fixed rib. The inner ring bolt can be designed eccentrically to set the

The rollers, idlers and pulleys for unit handling can be found in a wide variety of machines and devices - pallet or roller conveyors, lifting devices, etc. They are used to convey loose or packaged

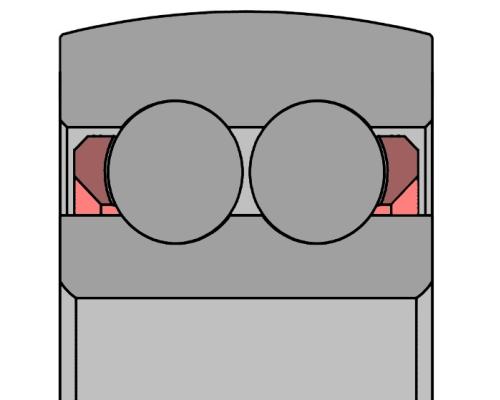

Track rollers correspond in their internal design to single or double row ball bearings and have a thick-walled, usually crowned outer ring. Optionally, they can be equipped with a combined inner ring

Track rollers with plastic coat correspond in their internal design to single or double row ball bearings and have an outer ring sheathed with plastic (typically polyamide). The outer ring is usually

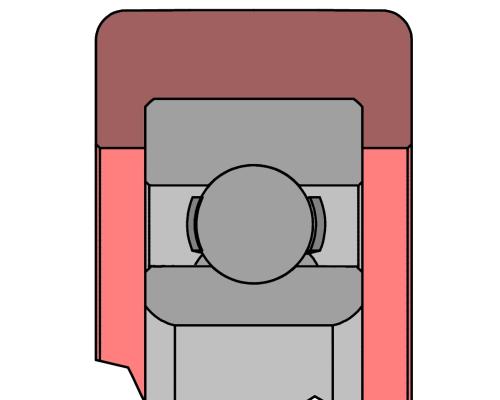

Our rolling bearings can be equipped with a wide variety of sealing systems, depending on the application. Seals are necessary to protect the rolling bearings when they are exposed to dust, dirt