Due to the ever-increasing demands on the availability of machines and plants, it is necessary to reduce the number of necessary maintenance intervals and to keep the time required to carry them out as short as possible. For this purpose, we offer a generation of rolling bearings and track rollers specially designed to be maintenance-free. Thanks to the special design of our maintenance-free products, we can offer you inspection-free operation throughout the service life of our products, even under extreme conditions that previously made regular relubrication indispensable, for example. Alternatively, you can achieve longer service lives by using our hybrid bearings compared to standard rolling bearings made of rolling bearing steel.

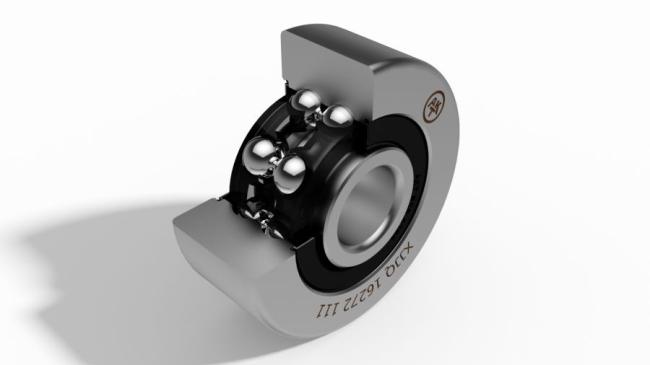

Maintenance-free track rollers and rolling bearings

- Use of solid lubricants

- Wear-reducing surface coatings

- optimized cage design

- basic design with frictionless steel sealing systems

- on request equipment with sliding seals up to 200 °C

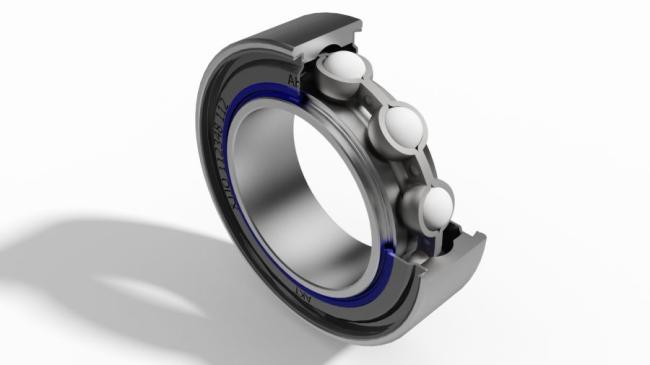

Hybrid track rollers/ -.rolling bearings

- Bearing rings made of rolling bearing steel with ceramic rolling elements

- because of the combination of materials, they are suitable as insulator suitable

- higher bearing stiffness than comparable 100Cr6 rolling bearings

- suitable for high speeds

- lower operating temperatures due to lower friction

- higher operating life due to self-lubricating effect of ceramic rolling elements

- suitable for oscillating applications where no sufficiently supporting lubricating film is formed

- equipped with frictionless steel sealing systems

- equipped with sliding seals up to 200 °C

For further information or inquiries about our hybrid bearings or maintenance-free track rollers, please contact our service team via the contact form at any time.

Your contact person

-

Roller bearings sales

-

+49 (2053) 497 - 36

-

Roler bearings

-

+49 (2053) 497 - 0

-

Opening hoursMo-Do.: 08:00 - 16:00

Fr.: 08:00 - 14:45

-

Delivery timesMo-Do.: 06:00 - 13:30

Fr.: 06:00 - 11:00

oder nach Absprache